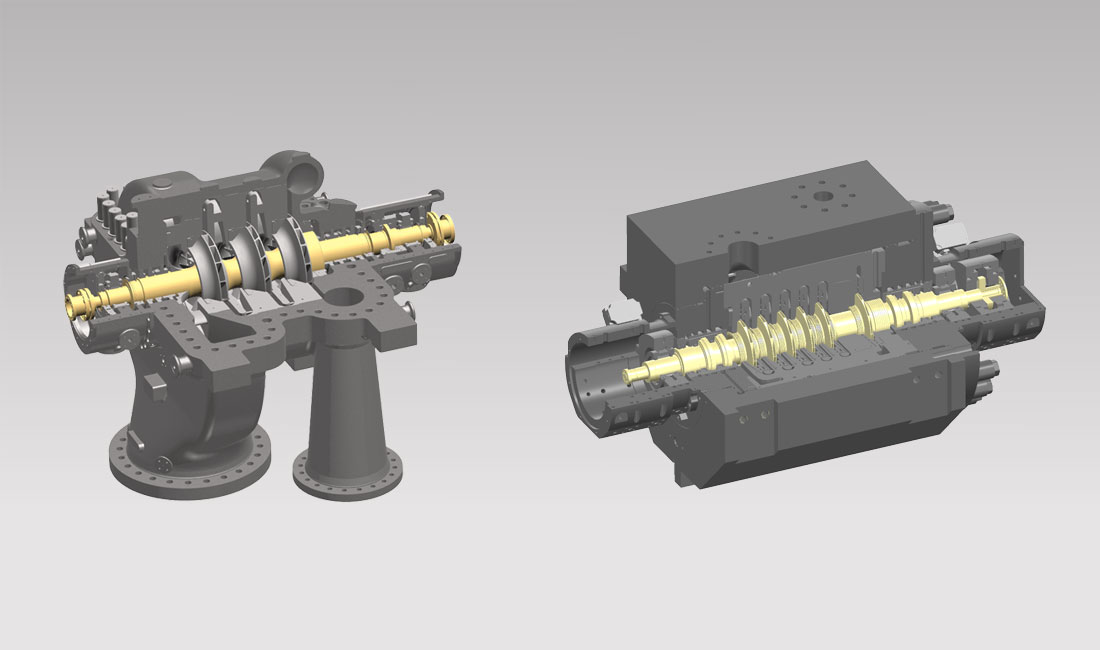

For many years, we support our customer in the design of a wide range of Turbo Compressors.

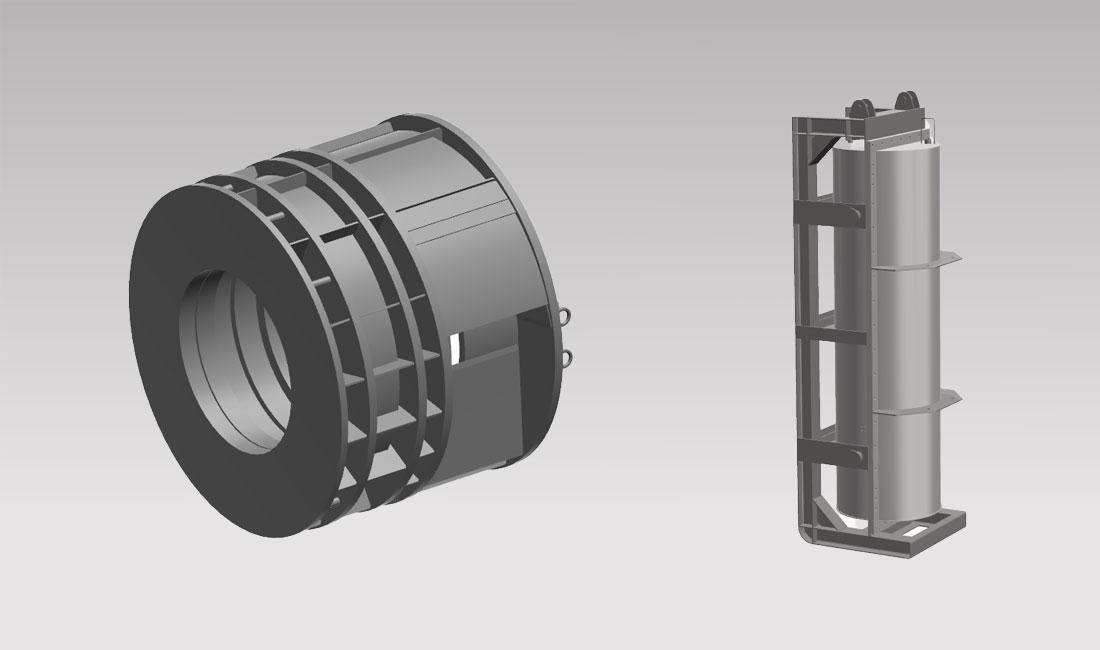

Axial compressors with optimized aerodynamics and high efficiency for large-scale applications.

Centrifugal Compressors which are tailored to meet specific pressure and flow requirements with a focus on compactness and reliability for chemical processing, refrigeration, and natural gas applications.

Barel Compressors for high-pressure environments with focus on the resilience and safety to meet the demands of heavy-duty industrial applications that require durability and efficiency.

Our detailed engineering expertise ensures that every aspect of the design of every project goes smoothly and according to a thoroughly developed plan.

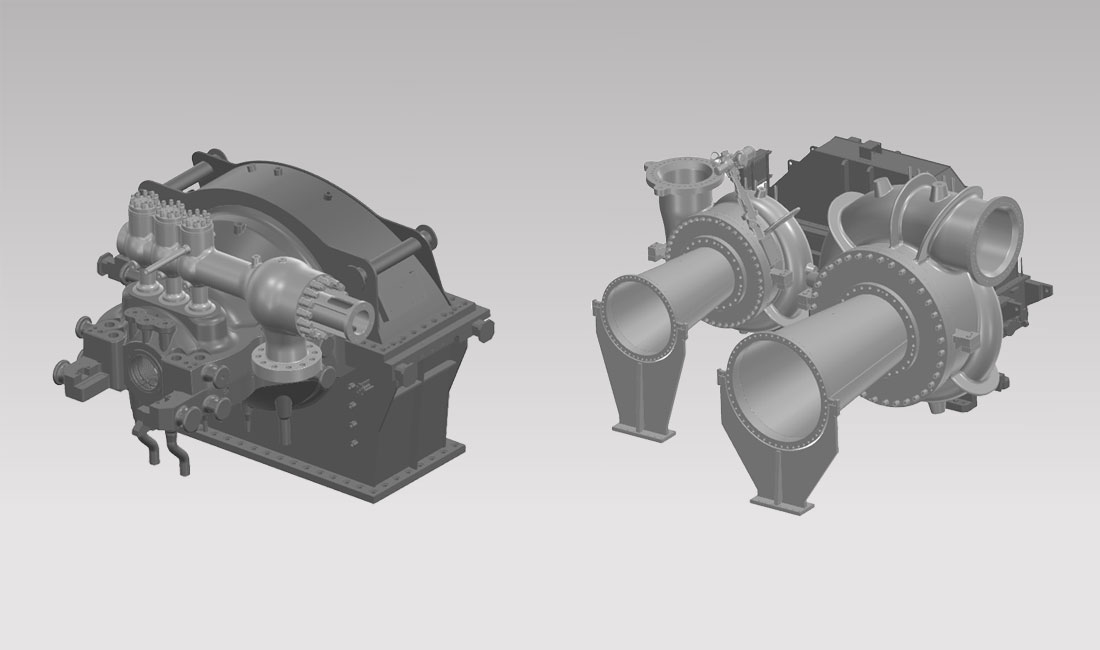

Our team assist in detail engineering of Centrifugal and Axial Expanders.

These machines deliver energy recovery with high efficiency helping industries to reduce energy costs and enhance system performance.

Gas or Steam Turbines, designed for maximal energy conversion and operational reliability.

We have provided comprehensive detail engineering support in several projects.

Working together with our client, we have proven that we can contribute to the successful detailing of various expander and turbine components, such as housings, stator, rotor parts, and others.

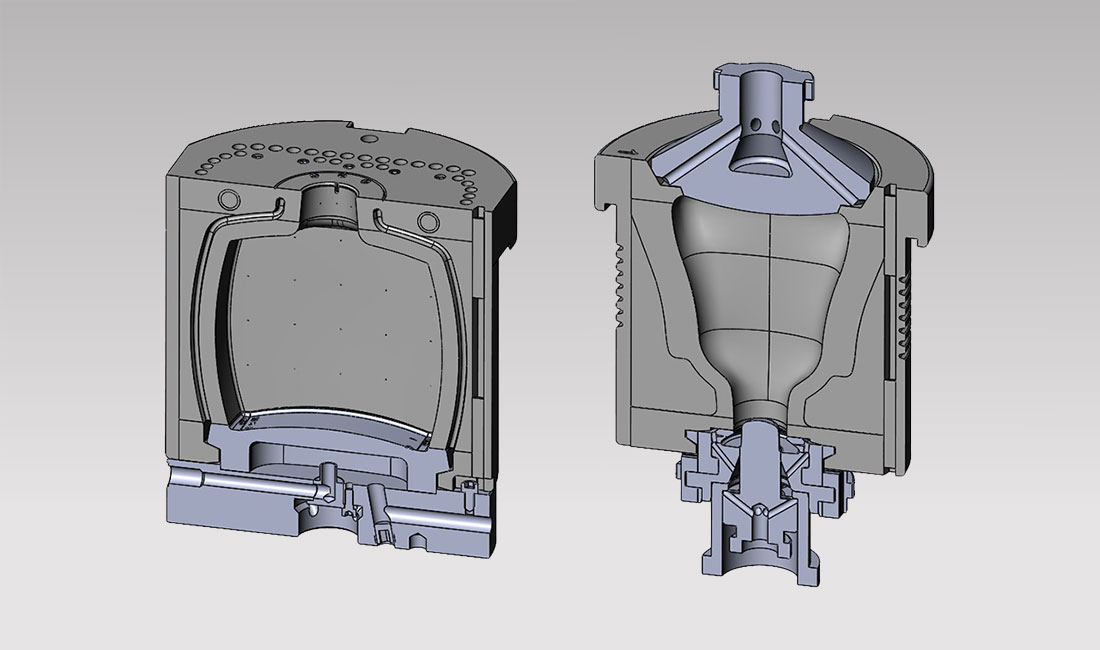

We offer complete 2D/3D design of glass container equipment with parison design and volume and shrinkage calculations. With almost a decade of experience and couple hundred projects behind us we can tackle any challenge, shape or form of glass bottle.

We can design vide variety of force cooled bottom plates, shaped parting line molds, engravings and decorations.

We specialize in the design and development of high-quality glass containers for various industries, including food & beverage, cosmetics, and pharmaceuticals. Our team combines aesthetics with functionality, ensuring innovative, manufacturable, and cost-effective solutions. Using advanced 3D design tools, we optimize shapes for branding, durability, and production efficiency. Whether you need a new bottle, jar, or custom glass packaging, we deliver precise, production-ready designs tailored to your needs.

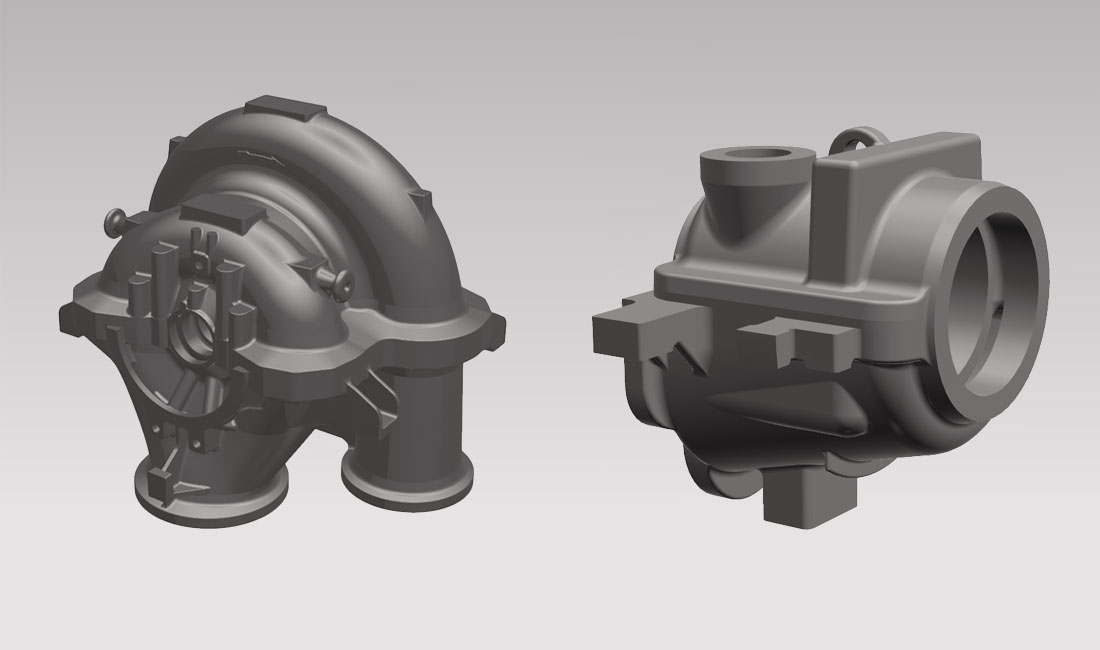

Over the years we have helped design and create many 3D models and drawings of castings according to customer requirements and have gained a lot of experience in the process. NX is certainly one of the most suitable tools for this job because it allows us to efficiently implement the initial design into finished 3D models and drawings ready to be sent to the foundry.

It has been shown that welded solutions often offer the best price-performance ratio, especially for large components.

We have made many welded components, which has given us experience in how to optimally design welded components and structures.

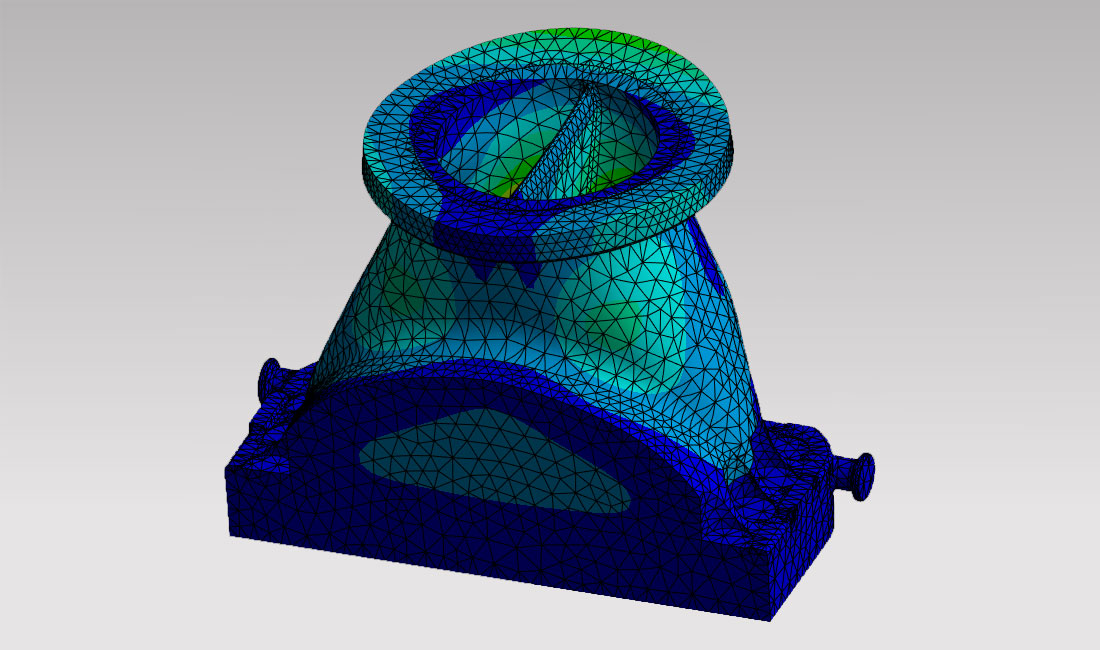

We can provide a wide variety of FEA analysis in Ansys with model preparation for it.

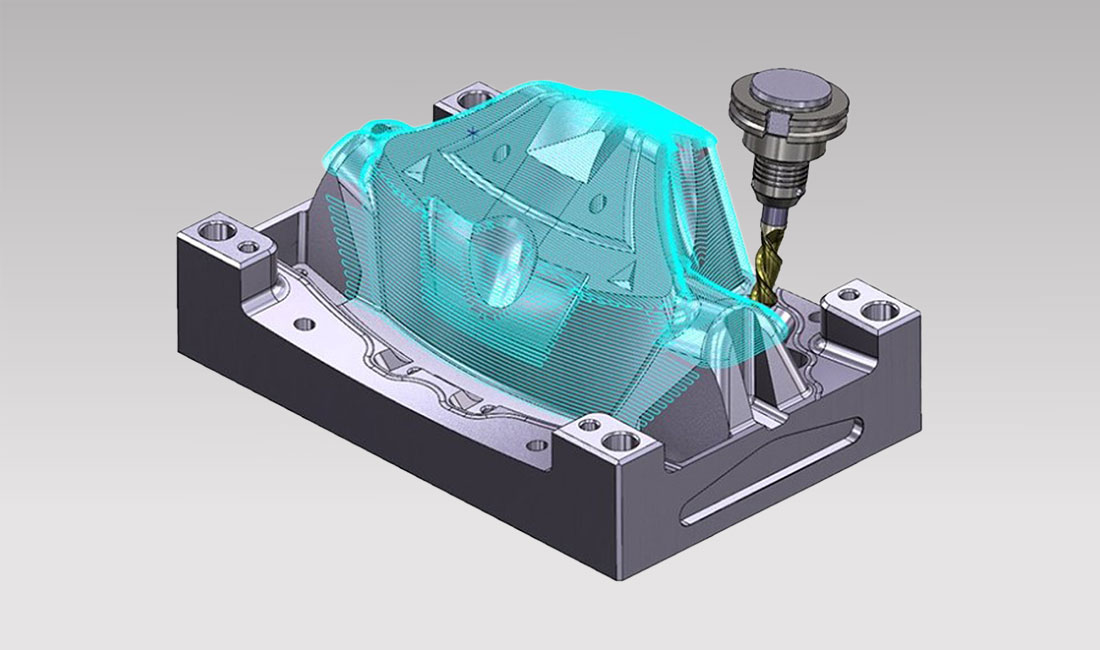

We can offer vide variety of CAM programming services. If its either improving your production or something entirely new we are here for you